Manufactory

davidh

2020-02-05T08:12:15+00:00

1986

1988

1991

The creation in March 1986 of a repair and maintenance workshop for harps, sales of accessories (trings, seats, etc.) located in the CIMA craftsmen’s building (Center International de la Mécanique d’Art), located « rue de l ‘Industrie » in Sainte-Croix, marks the start of the Manufacture de harpes David. Very quickly a new employee was hired for the home services of customers, who were then mostly in Switzerland.

On a client’s order, the first instrument is then made. It is a small 40 strings harp with simple pedal movement made on the basis of an old instrument. This development then requires the hiring in autumn of the same year of a second collaborator (mechanical technician). The first instrument of this type was put on the market at the end of 1986. It is aimed more at beginners because of its size and price. The woodwork part is then built in Italy while we manufacture the mechanical part. First subcontracted, the parts required for the mechanics are gradually being manufactured in the factory as equipment is added to various machines.

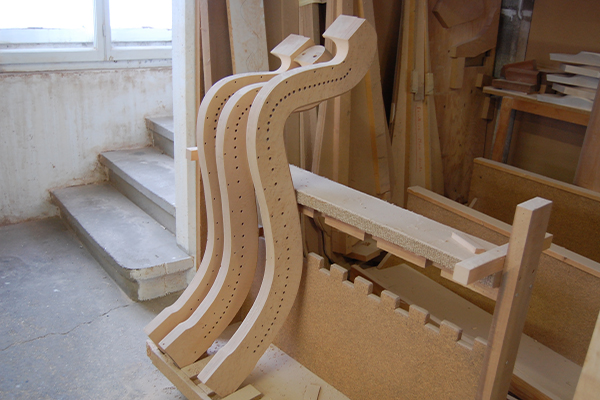

The workshop became too small and at the end of 1987 he moved to a larger room located on « Avenue de la Gare ». It is in these new premises that the workshop takes on larger dimensions: purchase of woodworking machines, equipment in computer-aided machines (cnc) for the manufacture of parts for mechanics, increase in the number of mechanical machines in general. The workshop now offers a wider range of instruments to cover almost all the wishes of a clientele that « internationalizes ». The instruments are exported to France, Germany first then to all the European countries where the harp is played. The order book is regularly stocked, 5 employees are then part of the workforce. Once again the surface becomes too small and a new move takes place at the end of 1991.

The new Manufacture David settles down « 22 rue des Rosiers » and finds its final address here. The years 1992/1993 are those which see our instruments exported to the United States, Japan, Turkey… Various points of after-sales service must then be set up, in particular in the USA and Japan, because the distance does not allow not an intervention as soon as possible. These branches also become resale points for our instruments.

The manufacture then turned to the production of « high-end » instruments which interested soloists, orchestras, educational establishments (from the simple school of music to the most famous national conservatories) but also demanding amateurs. Our catalog is regularly enriched and currently offers 8 « Wide Tables » models, 7 « Straight Tables » models and 4 « Celtic » models, as well as various accessories designed specifically for our harps.

The strength and specificity of our team of specialists lies in the fact that we are also able to fulfill any special request from the simplest to the most sophisticated. Thus, we are increasingly manufacturing “tailor-made” instruments: sculpture, gilding with 24-carat gold leaf, marquetry, decoration of the soundboard… From the creation of the initial diagram to the finalization the richest decor everything is undertaken in constant collaboration with the future owner. For gilding and marquetry work, we are attached to traditional techniques. The engagement in our workshops of a wood sculptor and inlayer allows us to meet all the specific requests that come to us from all countries and mainly from the Far East.

The concern of our current team is to constantly improve the instruments both in terms of sound, technical quality of the mechanics and its reliability, as well as in the rigor in the choice of materials and finishes. To this end, various experiments are still in progress, both for the mechanical part and for the woodwork part.

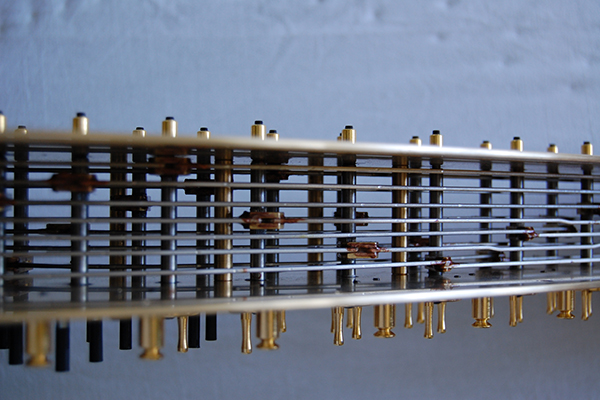

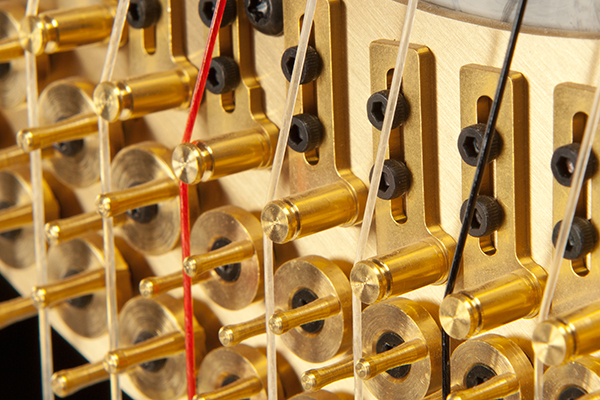

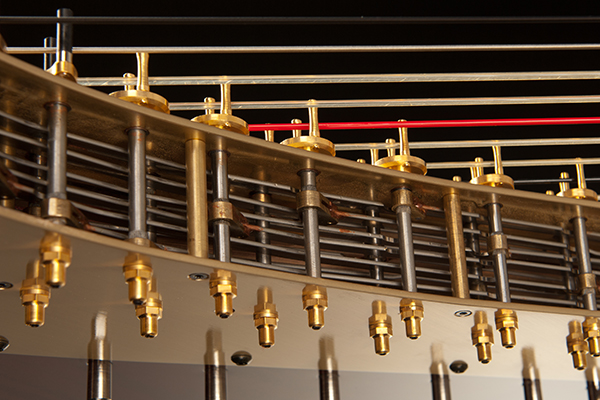

Our factory is located in Sainte-Croix, the Swiss cradle of precision mechanics for watches and music boxes. The inheritance of this know-how, associated with new technologies (computer-aided numerical control machines) allows us to guarantee our mechanics optimum quality and precision. The 1600 mechanical parts that make up our harps are all made in the factory, with the exception of a few screws.

We are constantly seeking to improve the sound quality of our harps by drawing on the experiences of our ancestors with regard to the provenance of the trees, felling at the most favorable period and specific debitage.

The laboratory of the Institut Fédéral de Technologie performs for us at Ecole Polytechnique de Zurich (EPFZ) very comprehensive analyzes of samples of spruce pre-selected as resonance wood. Each sample is analyzed according to the following criteria: density, elasticity modulus, speed of sound propagation, dendrochronology. The results of these analyzes make it possible to estimate the resonance coefficient and to validate or not this preselection. This scrupulous selection makes it possible to keep only the true resonant spruces, which are then sawn « on quarter » and cut into boards. These are then stored for many years in different hangars, at various altitudes and packaging. Drying takes place exclusively in air (we do not use accelerated artificial drying). They are then assembled to form the “resonance soundboards” of our instruments.

The Manufacture de harpes David has been present at the World Harp Congress (W.H.C. – World Triennial Harp Congress) since that of Vienna in Austria (1987).

At the Prague congress in 1999, a new design of the soundboard was presented, the sound obtained of which was then unanimously recognized. It opened the doors of the biggest orchestras, universities and conservatories of music as well as the interest of the most famous soloists.

Since then we have produced a specific model of harp for each World Congress, such as the « Green » for the Dublin congress (2005) or the « Marble » for that of Vancouver (2011).

The « Green » – W.H.C. Dublin (2005)

The « Marble » – W.H.C. Vancouver (2011)

The Manufacture de harpes David was present at the 13th World Harp Congress which will took place from July 7 to 13 in Hong Kong. We had the pleasure to present our harp specially made for this congress.